Efficient lighting in a warehouse includes more than installing a few bulbs here and there; it is an intricate balance of science and engineering. Understanding the unique requirements of illuminating such vast spaces is among the many responsibilities of warehouse owners and managers. A quick guide to optimizing warehouse lighting can significantly improve your facility’s operations, safety, and energy efficiency.

Plan Your Layout

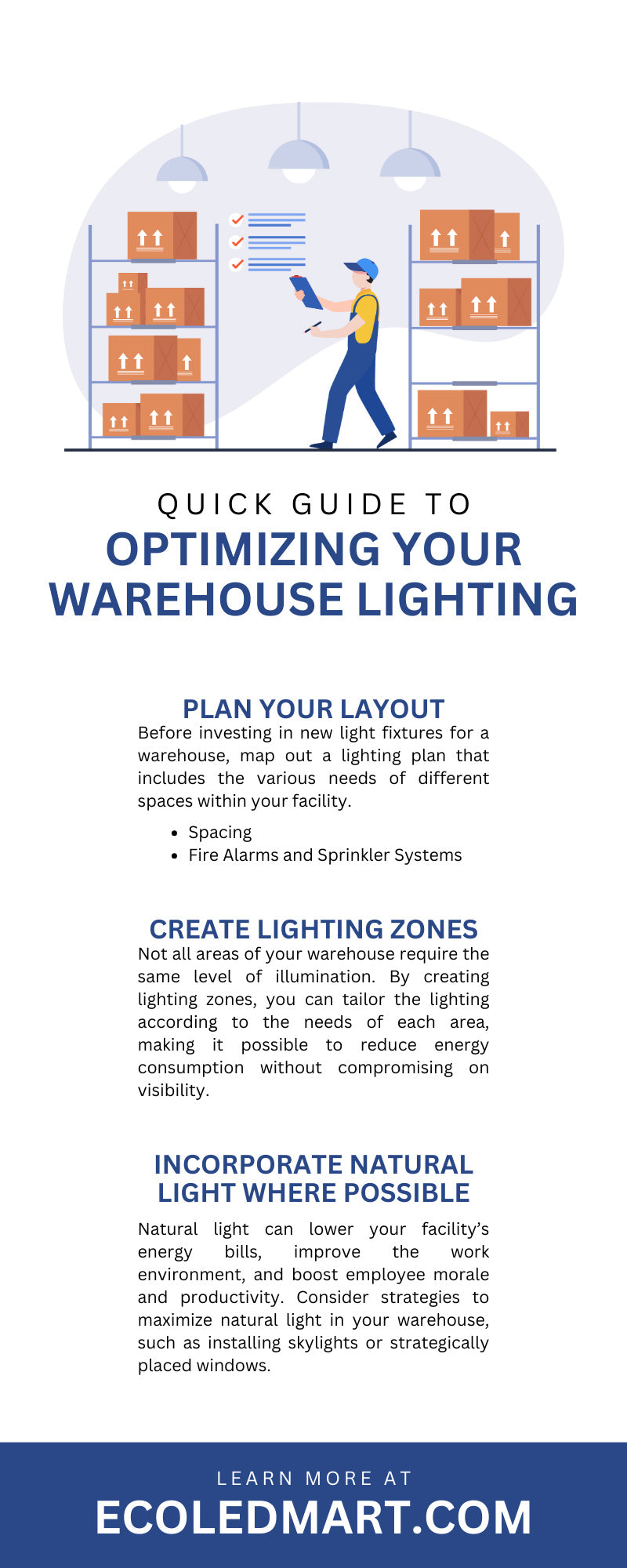

Before investing in new light fixtures for a warehouse, map out a lighting plan that includes the various needs of different spaces within your facility.

Spacing

Your warehouse’s design can help you determine how to set up your lighting system efficiently. The goal is to distribute light evenly across all areas without creating overly bright spots or leaving some areas in the shadows. Consider the height of your racks, the width of aisles, and the type of activities conducted in each area when planning your lighting layout.

Fire Alarms and Sprinkler Systems

Never obstruct safety systems, such as fire alarms and sprinkler systems, with lighting installations. Position the lights in a way that illuminates the space while not interfering with these critical safety features. This requires careful planning and consultation with warehouse safety experts and your local fire department.

Create Lighting Zones

Not all areas of your warehouse require the same level of illumination. By creating lighting zones, you can tailor the lighting according to the needs of each area, making it possible to reduce energy consumption without compromising on visibility. High-traffic zones, workstations, and areas where workers perform detailed tasks may need brighter, more focused lighting compared to storage areas.

In addition to the broader warehouse zones, give special attention to designing the lighting for employee break rooms and office areas within the warehouse. Unlike areas necessitating visibility, these spaces benefit from soft, warm light that creates a comfortable and relaxing environment for employees during their breaks.

In office areas where administrative tasks require staff to use computers, task lighting and blue light reducing or anti-glare screens can enhance worker productivity. This dual approach to lighting ensures the operational efficiency of the warehouse team and their well-being.

Incorporate Natural Light Where Possible

Natural light can lower your facility’s energy bills, improve the work environment, and boost employee morale and productivity. Consider strategies to maximize natural light in your warehouse, such as installing skylights or strategically placed windows. You must balance natural lighting with artificial sources for consistent illumination throughout the day.

Save Energy With LEDs and Motion Detectors

Saving energy is crucial to warehouse management for several reasons. Firstly, it leads to substantial cost savings on utility bills, which can significantly affect your bottom line. Secondly, it aligns with environmental sustainability goals. Reducing energy consumption minimizes the environmental impact of your warehouse operations, bolstering your commitment to eco-friendliness.

Additionally, energy-efficient practices can enhance the functionality and longevity of your warehouse’s lighting systems, decreasing the need for frequent replacements and maintenance. Adopting energy-saving measures is a financially savvy and ethically responsible strategy for warehouse management.

LED Fixtures

Light-emitting diodes (LEDs) have revolutionized warehouse lighting with their energy efficiency, long life, and superior light quality. Unlike incandescent bulbs, LEDs deliver consistent light output over their lifespan, which can reduce maintenance and replacement costs. They are also more durable than other lighting options, making them ideal for warehouses.

Motion Detectors

Pairing LEDs with motion detectors can further enhance energy savings by ensuring that lights are only on when needed. This is especially useful in parts of the warehouse with infrequent used. You can adjust motion sensors for sensitivity and range to ensure they operate effectively in your warehouse.

Consider Color Temperature

The color temperature of light, measured in Kelvin (K), impacts visibility, comfort, and even the mood of an area. For warehouses, a very bright color temperature ranging from 5,000K-7,000K (counterintuitively called “cool” light) resembling daylight can enhance visibility and worker alertness.

However, the best lighting choice for warehouse environments may vary depending on the tasks your team performs or personal preferences.

Note that warm color temperatures can improve the ambiance in spaces such as restrooms, conference rooms, and changing areas. A color temperature range of 2,700K–3,000K emits a softer, more yellow-hued light and creates a more pleasant and relaxing environment.

“Warm” lighting can ease the transition from the high-energy, brightly lit work zones to spaces meant for resting or working on personal tasks. Taking full advantage of a light’s color temperature is about striking the right balance between functionality and comfort and providing a calm retreat for your employees during breaks.

Illuminate High Ceilinged Areas With High Bay Lighting

Warehouses often feature high ceilings, which pose a unique challenge for lighting. Luckily, high bay lights can illuminate spaces with ceiling heights of 20 feet or more. They focus light downward to the floor, ensuring adequate visibility in such vast vertical spaces. LED high bay lights offer superior performance and energy efficiency compared to traditional high bay fixtures.

The Benefits of Linear Lighting

Linear lighting systems, which are modern and versatile solutions for warehouse environments, offer numerous advantages in aesthetics and functions. These sleek, elongated fixtures provide uniform, diffused light that can cover large areas without creating the harsh shadows or glare often associated with point-source lights. They will illuminate every corner of your warehouse, enhancing safety and productivity.

Additionally, commercial linear LED light fixtures are energy-efficient and have a long lifespan, which translates into lower utility bills and maintenance costs over time. You can easily integrate them into various parts of your warehouse, from workstations and aisles to loading docks. They’ll align with the specific requirements of each zone.

Optimizing the lighting in your warehouse requires thoughtful planning and consideration of several factors, from the layout of your space to the types of lights you choose. The key to effective warehouse lighting is installing the right lights in the right places. Eco LED Mart offers a wide range of LED fixtures that will surely meet the diverse needs of modern commercial spaces, including warehouses, ensuring both operational efficiency and sustainability.